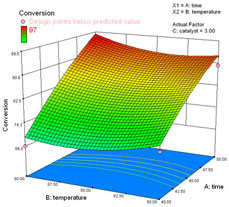

Solutions for most problems that Qualimation handles are derived and solved using analytical methods. These solutions prove to be very useful and provide excellent insight into the behaviour of many systems. DOE allows for multiple input factors to be manipulated determining their effect on a desired output (response). By manipulating multiple inputs at the same time, DOE can identify important interactions that may be missed when experimenting with one factor at a time. All possible combinations can be investigated using the DOE apprach. Qualimation has several samples of successful implmentation of the DOE tool in the quality improvement program. We also suggest you when not to use these methods and to start resorting to other means of analysis.

Design of experiments is a very powerful tool that can be utilized in all manufacturing/service industries. Quality managers who encourage DOE use will greatly increase their chances for making breakthrough improvements in product quality and process efficiency.

Design of Experiments (DOE) techniques enable designers to determine simultaneously the individual and interactive effects of many factors that could affect the output results in any design. DOE also provides a full insight of interaction between design elements; therefore, helping turn any standard design into a robust one.

In brief, DOE helps to pin point the sensitive parts and sensitive areas in your designs that cause problems in Yield. Designers then are able to fix them and produce robust and higher yield designs prior going into production.

What is Designed Experiments?

|