Overview

The SPC or Statistical process control is a control tool by which you could have full control of your process. The data that is collected is used to plot a graph that gives valuable inferences about its Quality and feed back. SPC is an integral part of any Quality Improvement program. It is basically a tool for controlling the variables that add value to a process. We at problem solving institute try to make the statistical procedures and theorems simple and application driven so that you will find learning and applying SPC to be fun.

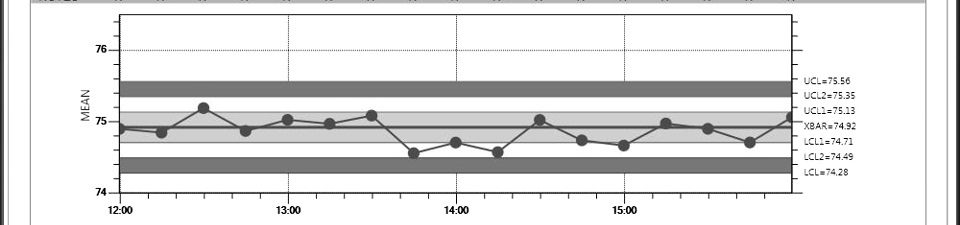

SPC provides real time analysis to establish controllable process baselines; learn, set, and dynamically improve the capability of the process.

SPC is an important component of any Six Sigma program and the first choice in improving and controlling the processes. Learn the power of SPC ,statistical charts and output. Learn how to identify shift due to causes that you are supposed to control and those that are due to chance... Read More

BENEFITS

- 1 Monitors and provides feedback for keeping processes in control.

- 2 Triggers when a problem occurs

- 3 Differentiates between problems that are correctable and those that are due to chance.

- 4 Gives you better control of your process

- 5 Reduces need for inspectio

- 6 Provides valuable knowledge in the working of the process

NEED FOR SPC

You need SPC in the following situations

- a When controlling ongoing processes by finding and correcting problems as they occur.

- b When predicting the expected range of outcomes from a process.

- c When determining whether a process is stable (in statistical control).

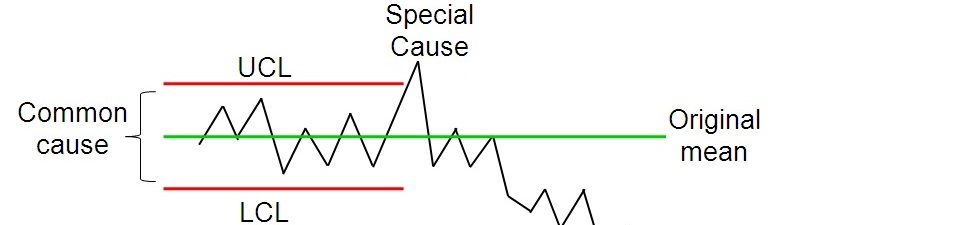

- d When analyzing patterns of process variation from special causes (non-routine events) or common causes (built into the process).

- e When determining whether your quality improvement project should aim to prevent specific problems or to make fundamental changes to the process... Read More

Objective

Based on experience & competency in the NDT methods personnel are Qualified as

Determine if a controlled process is Yielding an adequate degree of control

Improve Quality of the product or service.

Be used as feedback for redesigning the product or service.

Supplement the Design robustness of a product.

Solve the problem and control the variables that cause deviation.

TRAINING/CERTIFICATION

Invest in your career and future by earning a Qualimations certification in Quality Assurance through its QA/QC training and certification. Gain the edge and beat competition, increase your potential for a higher salary.

Testimonials

The course is very excellent and content is good, the practical and case studies is very good. The time of delivery / Handson.

S.Sathish, Asst Prof, Sri Ramakrishna Engineering College

I have improved my knowledge in this course. Lot of awareness about controlling the defect. This is very useful for my career and improves the Quality level in the organisation.

K.Vinoth Kumar, Quality Engineer, APEX Bright Bars, Coimbatore

The course is very good and useful to me. I got lot of ideas from your teaching, your way of training is simple and superb.

S.Meiyazagan, MBA, ANNA University

Very useful and clear,

V.Bharathi, MBA, Anna University

The course is good and learned a lot in this session. At a design level plan to use this for product development in developing a defect free product and with minimum cost.

Elavarasan. S. R&D , KNR Company

Excellent!!!, I have clearly understood how to approach the DPMO and PPM options. The X bar chart and its actual importance is very clear now.

N. Vijaya Kumar, Production Incharge, Viking Industries

It was a very interactive session, lots of practical application for service and production sectors.

Sumesh, Research Scholar, Anna University

This course is useful for academic and industry. The way of explanation with practical solution is very easy to understand. No matter what business you are doing 6 sigma is critical.

Dr.P.Sivaprakash, Associate Professor, ASL Pauls college of Engineering and Tech

The course is very useful for management graduates, i already know TQM, still felt the application of 6sigma is deep and useful.

Umaashankar.V, MBA Student, Anna University

The course is well planned out and effectively handled, covered basics and all credentials needed for Six Sigma. I was able to understand the concepts well, the examples quoted gave a real time picture for understanding.

K.Karthikeyan, Assistant Professor, K.V. Institute of Management and Information Studies

SPC & SIX SIGMA

SPC is an important component of any Six Sigma program and the first choice in improving and controlling the processes. Learn the power of SPC through us....

- * Identify what characteristics to be controlled

- * Establish Control limits

- * Find how to control the process

- * Learn how to measure improvement of a process

- * Learn how to detect shift and how to set alerts that take action... Read More

What is SIX SIGMA?

Six Sigma means a measure of quality that strives for near perfection. Six Sigma is a disciplined, data-driven approach and methodology for eliminating defects (driving toward six standard deviations between the mean and the nearest specification limit)... Read More